3D Printing Fume Extraction System

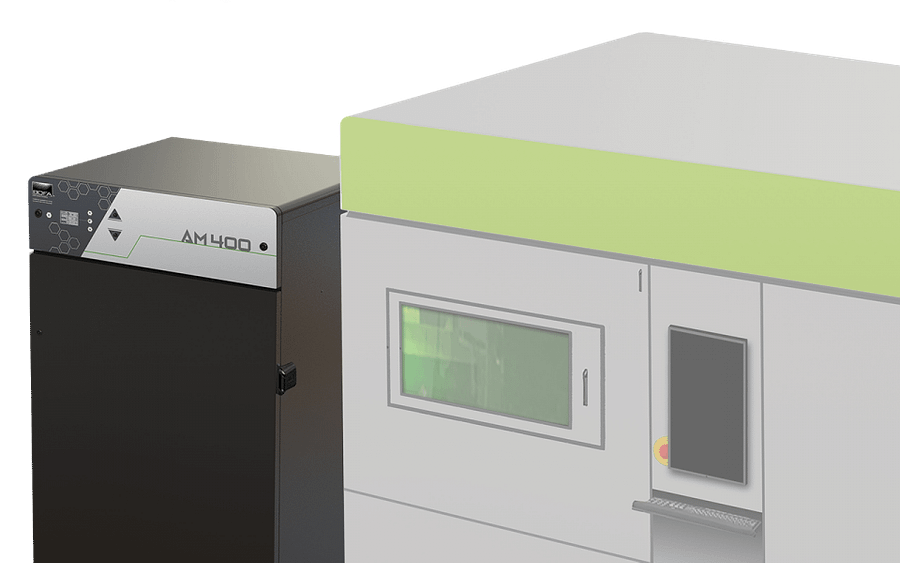

BOFA’s 3D PrintPRO models deliver effective fume extraction and filtration rates in compact machines, with optional speed control, to keep the print area clean and return ultra clean, filtered air to the operator breathing zones.

United Spectrum company is a leading distributor for BOFA (UK) industrial fume extractor system and offer BOFA Laser Fumer Extractor, BOFA HEPA filters, BOFA Combined Filters, BOFA Pre-Filters in India.

3D Printing Fume Extraction System

United Spectrum company is a leading distributor for BOFA (UK) industrial fume extractor system and offer BOFA Laser Fumer Extractor, BOFA HEPA filters, BOFA Combined Filters, BOFA Pre-Filters in India. BOFA’s ADVANTAGE range of laser fume extraction and filtration systems are designed for applications that generate particulate and gaseous volatile organic compounds (VOCs) within the laser coding, laser marking, laser cutting and laser engraving industries. Our laser fume extractor units have been designed so that a number of manufacturers’ laser engravers can sit on top of the extractor, effectively, doubling up as a work station.

ADVANTAGE range

By maintaining a dust-free operating area, our systems help to protect valuable equipment, maintain a higher quality mark and reduce the number of rejects and contaminants.

Open loop

A configuration in which the BOFA fume extractor system draws air from the 3D printer, filters it, and then pushes it out into the surrounding environment. The 3D printer suffers a net heat loss as a result of this arrangement. When trying to keep air temperatures lower than they would be if printing without extraction, this configuration can be beneficial.

Closed loop

A setup in which the BOFA fume extractor system pulls air from within the 3D printer, filters it, and then pushes it back in. The 3D printer’s heat stability or increases as a result of this setting. When trying to keep air temperatures higher or more steady than they would be if printing without extraction, this configuration can be useful.

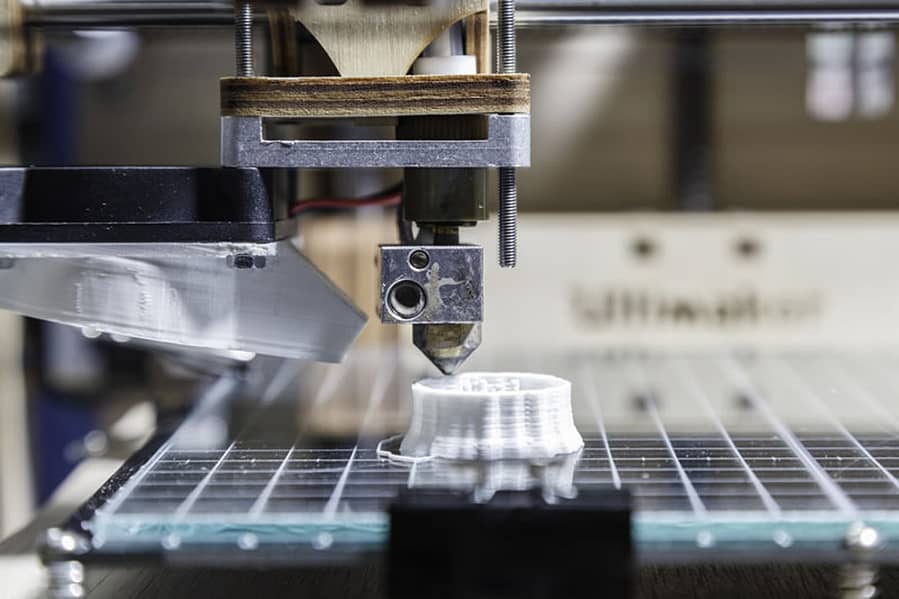

Fused Filament Fabrication

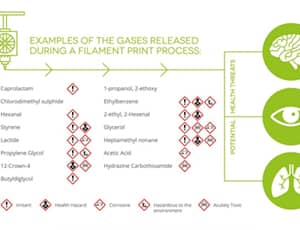

In the Fused Filament Fabrication method, filament is extruded through a nozzle and onto a heated bed, where a component is printed layer by layer. The technique can produce debris and particulate emissions during these prints. This by-product can settle around the guts of the 3D printer and onto expensive mechanical components over time and depending on the material. If not removed, this contamination can cause mechanical motion to be disrupted, reducing part precision and quality while also increasing wear levels on the afflicted components. BOFA fume extraction systems with BOFA HEPA / BOFA combination filters can assist eliminate these undesired by-products, resulting in considerable quality and durability advantages.

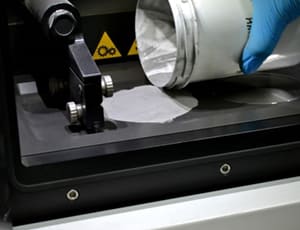

Directed Energy Deposition

Powdered material is used in both the Directed Energy Deposition and Binder Jetting procedures to construct and rebuild components. There is movement inside the build chamber throughout these processes, which can cause powder to settle in undesirable locations and hence not be utilized during the build. This powder waste not only costs the user money, but it can also have a negative influence on print quality and component durability. The BOFA fume extraction system with BOFA HEPA / BOFA combination filters can assist in the removal and recovery of lost powder, resulting in cost savings, improved component quality, and machine life extension.

Videos

Gallery

Enquiry

For BOFA 3D Printing Fume Extractor System enquiry and to discuss more about your application requirement, with one of our laser engineer. To know BOFA 3D Printing Fume Extractor System price, BOFA HEPA Filters, BOFA Combined Filters, BOFA Pre-Filter Price in India. Please call us direct on +91 9789904948 or visit our regional office or complete the request form and we will contact you, as soon as possible. We United Spectrum company also offer the best quality laser marking, laser cutting, laser texturing, laser engraving, laser cleaning, laser welding, laser cladding, laser hardening, laser shock peening, laser micro machines in India.