Battery operated laser marking machine

If you are looking for a distributor, supplier, manufacturer of compact battery operated laser marking machine in Chennai, Coimbatore, Cochin, Hyderabad, Bangalore, Mumbai, Thane, Pune, Ahmedabad, New Delhi, Gurgaon and Noida. We United Spectrum company offer the best ultracompact DPSS laser marking machine in India.

Compact battery operated laser marking machine is ideal for micro laser drilling, micro laser cutting, micro laser selective layer removal and laser marking of circuit boards.

Microscope image size ca. 4 x 4 mm²

Microscope image size ca. 4 x 4 mm²

Battery operated laser marking machine

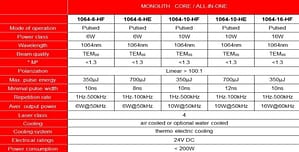

We are the official partner for Compact Laser Solutions GmbH (Germany) for Indian territory. Ultra-compact, Q-switched OEM laser sources with wavelengths of 1064 nm (16W), 532 nm (12W) or 355 nm (6W) for material machining and marking applications. Also under extremely non-versatile space conditions, the miniature scale of the MONOLITH sequence enables easy device integration.

MONOLITH CORE: Miniature laser head of only 122 x 122 x 122 mm³ (incl. cooling-unit) with a weight < 3 kg. Can be combined with an ultra-small, palm fitting controller of only 150 x 150 x 115 mm³ (incl. cooling unit)

Pro: Maximum integration capability

MONOLITH CORE: Miniature laser head of only 122 x 122 x 122 mm³ (incl. cooling-unit) with a weight < 3 kg. Can be combined with an ultra-small, palm fitting controller of only 150 x 150 x 115 mm³ (incl. cooling unit)

For rapid prototyping of complex structures, laser machining is particularly suitable. The introduction of direct laser writing using digital layouts, for instance, is a simple technique to support and test new product technologies. But laser machining also provides new possibilities for slim production chains and lower production costs in batch production.

A highly versatile machining activities, such as laser drilling, laser cutting, laser selective layer removal and laser marking of circuit boards, is characterised by a well-configured laser workstation. We remain based on your application objectives within the context of our service offer, recommending the most suitable laser source with the appropriate implementation plan, and evaluating the potential solutions in our laser application laboratory for you.

Pro: Maximum integration capability

- Laser marking can be implemented by inducing very different material reactions, for example by

- Heating, e.g. for black annealing markings on steel

- Material removal, e.g. for engravings on silicon or ceramics

- Layer removal, e.g. for the inscription of anodized aluminium

- Carbonization, e.g. for the blackening of polymers

- Bulk modifications, e.g. for the generation of localized micro-cracks or micro-dots

- The application orientated choice of the right laser parameter (wavelength, average power, repetition rate, single pulse energy and fluence) is related to the desired material reaction, the required working field area and the maximum processing time available.

- We strongly recommend a sample marking test in our application laboratory. This service is free of charge.

- Average power: 16 W for 1064 nm, 12 W for 532 nm, 6 W for 355 nm at 40 kHz

- Short laser pulse width: 4 to 10 ns

- High single pulse energy: e.g. 500 µJ at 355 nm and 6 kHz

- Significant single pulse peak power: up to 100 kW

- Arbitrary repetition rate: 1 Hz to 500 kHz

- Multiple Pulse Control (MPS) function

- Expectable 100,000 hour life-time for the one diode-pump module

- Air-cooling, water-cooling also available for e.g. clean-room processing

- Also available as complete marking system with software package

- Made in Berlin, Germany

Videos

Information

- Extensive selection of functions and laser controlling options

- Embedding graphics

- Different code modules (data-matrix, QR-code, barcode)

- True Type fonts, Single Line fonts, Unicode characters

- Text and graphic rotation und free scalability

- Circle labelling

- Implemented CAD programs

- Implemented image processing

- Projection free circumference writing

- Automatic serial numbering, date- and time-functions

- Extensive help library available

- Laser parameter control with Start-Stop operation

- Support functions for axis-control (X, Y, Z and C)

- Support functions for industrial steering

- Functionality and user friendly handling has the highest priority when developing marking software. Compact Laser System offers a versatile and modern Visual Laser Write (VLW) software solution

- Programs run under Windows

- Easy operation of flowchart functions

- Straightforward WYSIWYG implementation

- Laser control capability via serial interface (RS 422) or USB

- Free programable digital-ports und functions (Visual Basic Script)

Enquiry

For ultra-compact DPSS laser marking machine enquiry and to discuss more about your application requirement, with one of our laser engineers. To know the ultracompact laser marking machine price, ultracomact DPSS laser marking samples, please call us direct on +91 9789904948 or visit our regional office or complete the request form and we will contact you, as soon as possible. We United Spectrum company also offer the best quality laser marking, laser cutting, laser texturing, laser engraving, laser cleaning, laser welding, laser cladding, laser hardening, laser shock peening, laser micro machines in India.