Compact Laser Micro-Machining System

From the laboratory research to PCB production industry, the most compact laser micromachining system is available. This desktop-sized laser micro macine could be beneficial for biological sensors, medical sensors, solar thin films and micro correction of electronic device, among other things.

The development of revolutionary laser micro processing tools and systems, particularly in the field of micro and nano-processing of advanced materials, is the focus of a team of laser application experts.

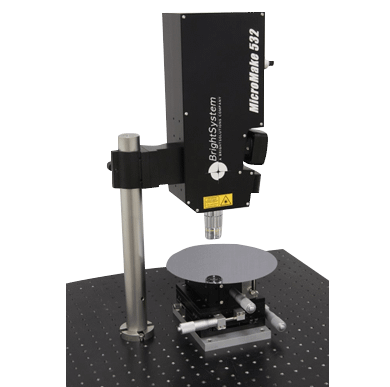

compact laser micro-machining System

United Spectrum Instruments company is proud to offer the world’s best compact laser micro machining system to the clients in India. The compact laser micro machining system is made by Bright System (Italy), which is superior in quality and good support. We are the leading supplier of high precision, high quality, highly reliable compact laser micro machining system in India. This compact laser micro machining system is ideal for the academic research institutions, government organisations and production

The primary areas of action are as follows:

- laser micro machining sysytem solutions for micro-corrections in electronics (masks, displays, OLEDs, RF circuitry, precision trimming)

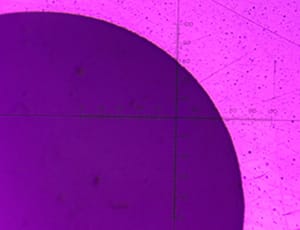

- laser micro machine solutions for processing optical materials (glass and polymers)

- laser micro machining process of innovative materials

Precision laser cutting is a method for obtaining extremely clean cuts in a variety of materials. Pulsed lasers lessen the thermal effect that CW lasers typically produce, resulting in a smaller heat affected zone. Thin polymeric substrates and thin metal sheets can be cut with these laser sources.

- Thin film removal on hard substrates

- Selective metal removal on ceramic substrates

- Microcorrection on wafers, masks and displays

- Microdrilling on metal alloys and transparent dielectrics

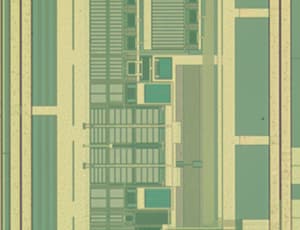

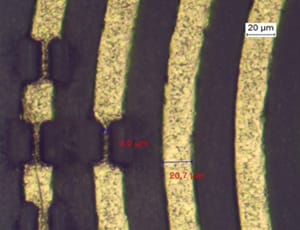

A micromachining laser workstation with high spatial resolution can fix manufacturing faults in electronic devices (such as OLEDs, masks, displays, semi-conductor devices, and printed circuits). Short pulses and close focussing enable for precise and selective ablation of the machined sample. This laser method is distinguished by its ability to ablate tiny layers in a very clean and controlled manner while avoiding harm to the substrate. Correction of RF circuits and components, displays, and many other thin film devices with a minimum ablated feature in the region of a few micrometres. laser micro correction on electronic device for various PCBs, such as FR4, CEM-1, Phenolic paper, ceramic substrates and solder mask.

- 3D direct microstructuring

- Precision surface texturing

- Track interruption on PCBs

- Micro-coding, Anti-counterfeiting

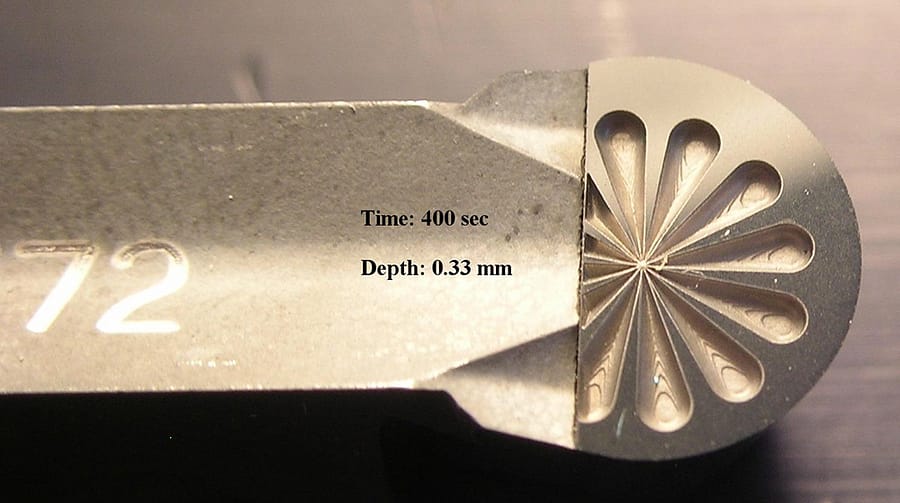

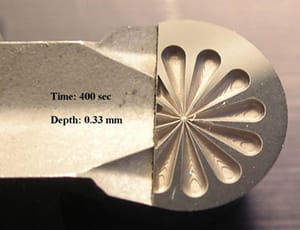

With the use of laser ablation, arbitrary features can be milled out of a sample surface using the micromilling technique. By carefully focusing a ns laser on the sample surface, deep features can be created with little damage or cracking. With the development of new laser sources capabilities and affordability, laser micromachining of hard and brittle objects is becoming more popular. It is a versatile, efficient, and quick technique to get results that were previously unattainable. Material removal can be managed to enable the machining of miniature forms with a limited heat affected zone by using a laser beam with a small laser beam spot size, high power, and short pulse. Laser micro machines can be used to shape brittle materials with crisp, well-defined geometries as well as hard materials like Inconel.

Gallery

Enquiry

For compact laser micro-machining system enquiry and to discuss more about your application requirement, with one of our laser engineer. To know the laser micro-machining system price, laser micro-machining samples, Please call us direct on +91 9789904948 or Visit our regional office or complete the request form and we will contact you, as soon as possible. We United Spectrum company also offer the best quality laser marking, laser cutting, laser texturing, laser engraving, laser cleaning, laser welding, laser cladding, laser hardening, laser shock peening, laser micro machines in India.