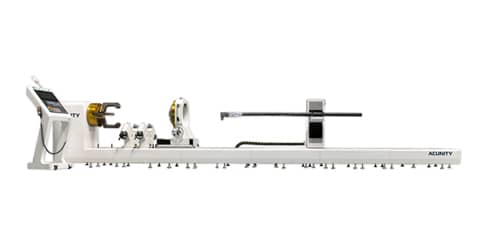

Internal Laser Cladding Machine

If you are looking for a distributor, supplier, manufacturer of External Laser Coating Machine in Chennai, Coimbatore, Cochin, Hyderabad, Bangalore, Mumbai, Thane, Pune, Ahmedabad, New Delhi, Gurgaon. We United Spectrum company offer the best fume extraction systems in India.

Internal Laser Cladding Machine

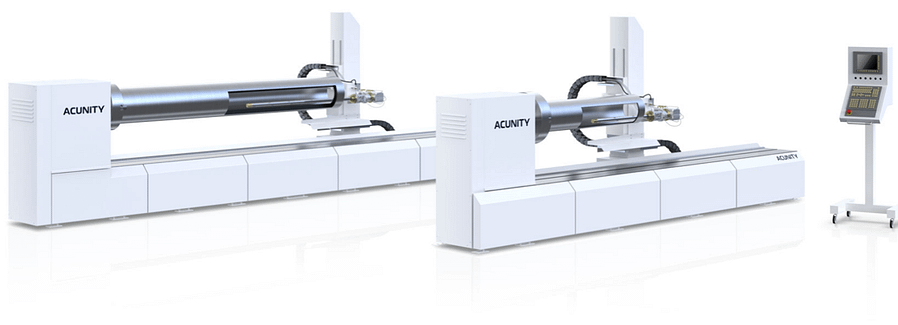

United Spectrum Instruments company is the official partner of ACUNITY GmbH laser systems in India. Internal laser cladding or Internal laser coating system, on the other hand, refers to a laser process in which a laser system is used to deposit material inside a hollow component, such as a pipe or tubing. This laser coating system is typically used to repair or reinforce the interior of a component, such as by adding a layer of material to the inside of a pipe to repair damage or to improve its structural integrity.

Both External and Internal laser cladding systems have similar process parameters , the main difference is the location of the substrate or the component that is being coated or clad.

The internal laser cladding machine typically includes several key components:

- Laser source: This is the device that generates the laser beam that is used to melt the material being deposited.

- Laser Beam delivery system: This is a set of mirrors and lenses that guide the laser beam to the surface of the substrate.

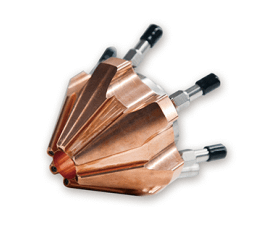

- Powder feeder: This is a device that delivers the material to be deposited to the surface of the substrate.

- Fixture jig: This is a device that holds the part in place during the cladding process.

- Control system: This is a computer-controlled system that manages the movement of the laser beam and the powder feeder, as well as the temperature and other process parameters.

- Cooling system: This is a system that cools down the substrate after the laser cladding process is completed.

Depending on the application and the type of material to be coated, the machine may have additional features like a robotic arm for automating the process, a chamber for vacuum or inert atmosphere, multiple laser sources etc.,

United Spectrum Instruments offers an internal laser cladding machine which is a specialized tool used for applying a coating to the internal surface of a hollow workpiece. The process typically involves directing a laser beam into the interior of the workpiece while simultaneously feeding a powder or wire material into the interior. The coating material melts and fuses to the surface, creating a new layer of material.

This type of interior laser coating machine is commonly used in industries such as aerospace, automotive, and oil & gas for the repair or modification of internal parts such as engine components, turbine blades, and piping. It is also used to enhance the wear resistance and corrosion resistance of internal surfaces.

The internal laser cladding process is considered to be a highly precise and efficient method of applying coatings to internal surfaces, as it allows for the accurate control of the coating thickness and distribution. Additionally, it offers a high degree of flexibility in terms of the types of materials that can be used as coatings.

- Zoom processing optics and high-precision EHLA powder nozzle,

- Variation of the laser beam diameter,

- High-efficiency powder feed and powder utilisation (only a slight excess),

- Repeatability: X ± O.O2 mm, Z < ± O.O5 mm per m,

- Crash sensor for active detection and emergency stop during collisions,

- External cooling unit for laser, optics and nozzle,

- CE declaration of conformity and type plate,

- (according to Machinery Directive 2OO6/42/EG, Annex II, Part 1A),

- Operation manual hardcopy and digital,

- Location and type of media and power supply interfaces according to customer requirements,

- Data editing fast: USB, LAN,

- Mass flow controller for inert gas (Ar),

- Length compensation: thermal expansion compensation system.

- Z-axis: Rack drive and linear guides, hardened steel rail

- X-axis: Linear unit (spindle drive) with 4 precision steel shafts, maintenance-free

- Linear unit (spindle drive) with 4 precision steel shafts, maintenance-free

- Linear axis: servo motor (B&R), maintenance-free

- Repeatability: X ± O.O2 mm, Z < ± O.O5 mm per m

- Positioning accuracy: X ± O.1O mm, Z ± O.1O mm

- Control: B&R, offline programming possible

- Railway : Repair and cladding of wheel, axles

- Mining : Long-lasting corrosion protection of hydraulic components for mining.

- Steel production : Wear protection for highly stressed rollers in the steel industry.

- Offshore-Industry : Protection of hydraulic cylinders against wear and corrosion in maritime environments.

- Petrochemistry : Corrosion protection of heat exchanger tubes in the chemical industry.

Laser Cladding on Steel of thin tube

Laser cladding on 316 stainless steel of thin tube

Laser Cladding on Steel base – super hard coating

Laser Cladding on stainless steel base – TC4 Ti-alloy Coating

Laser Cladding on steel base – Cu-alloy coating

Videos

Gallery