Micro Laser Patterning Machine

Micro Laser Patterning System for Fabrication of Micron Structures

We United Spectrum company offer the best quality laser micro cutting, laser micro drilling, Laser 3D Micro Milling, Laser Scribing, Laser Ablation, Laser Patterning, Laser Etching, Hybrid Laser Micro Machining System in India. United Spectrum company is the official distributor of M-Solv Ltd. (UK) company products for Indian market.

Micro Laser Patterning Machine

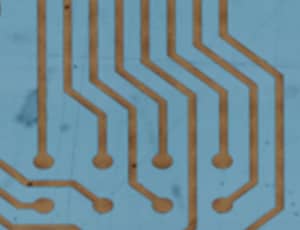

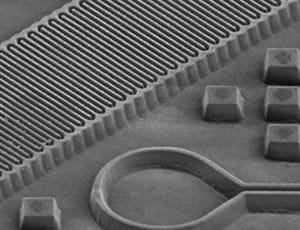

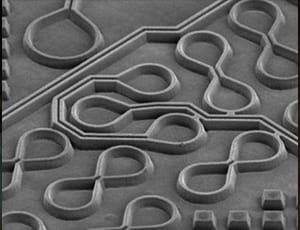

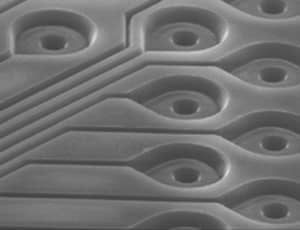

Laser patterning applies to the ablation, elimination or structuring in the thickness range of up to a few microns of thin usable layers on glass in our concept. Laser Patterning machine is equipped with multi-head, direct write, step and scan laser patterning tool that has been designed for simultaneous processing on opposite sides of thin panels. Laser beams are specifically irradiated onto translucent conductive films that shape a film on glass substrates and film components, such as ITO and metallic thin films of Cr, Al and other alloys. This approach facilitates the production of system patterns at high-speed and high-precision. This laser micro patterning machine is ideal for thin-film multilayer trimming application

Transparent Conductive Oxide (TCO) thin films made of Indium Tin Oxide ( ITO) are popular for both Flat Panel Displays (FPD), Solar Cells and Touch Panels technologies. The ITO acts as a clear chain, interconnecting transistors and pixels on the back plane of column and row drivers, or on the front panel of touchscreens, providing conductivity and light transmission.Conventionally, using photolithography, this complex pattern is developed and is the most commonly used technique used by manufacturers in the industry. The ITO is patterned through a sequence of masking, projection and wet chemical etching processes before progressing to corresponding phases of the manufacture of the unit. TCO laser printing, as an alternative to wet chemical etching, is the direct writing of patterns in a single phase process. Laser manufacturing TCO requires laser content ablation, which consequently eliminates time and pollution, thus providing cost-effective and environmentally friendly bulk output.

- Laser Patterning on Thin film solar cells

- Laser Patterning on large area electronics

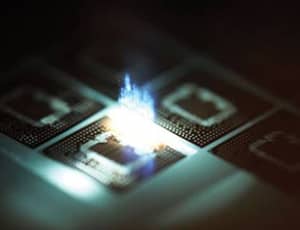

- Laser Patterning for advanced IC packaging

- Direct processing

- High-speed patterning

- High-accuracy processing

- Laser processing

- Advantages of Laser Micro Patterning

- High Precision

- High Quality

- No Physical-chemical Alteration

- Burr Free laser processing

- Precise laser patterning

- Crack Free laser processing

- No Heat Affected Zone

- All Materials

- Laser Patterning Materials

- Laser Patterning of Ceramic substrate

- Laser Patterning of Silicon Wafer

- Laser Patterning of Silicon Carbide

- Laser Patterning of Sapphire

- Laser Patterning of GaAs and GaP Wafer

- Recommended Lasers for patterning

- Single-mode QCW lasers

- multi-mode QCW lasers

- UV ns pulsed lasers

- green ns pulsed lasers

- picosecond lasers

- femtosecond lasers

- High throughput

- Dual board processing

Simultaneous dual sided and dual pattern processing - Automated robotic board loading

- As thin as 10um trench width

- Scan field up to 50mm x 100mm74Dual UV 355nm lasers

Dynamic focus compensation

Dynamic focal spot size control - Dynamic laser power control

- Class 1 laser safe enclosure

Touch panel operation - Ultra stable granite construction

- Vibration isolated machine core

- Laser Micro Cutting

- Laser Scribing, Laser Ablation

- Laser 3D Micro Milling

- Laser Micro Hole Drilling & Laser Blind Hole Machining

- Laser Patterning & Laser Etching

- Laser Selective Material Removal

- Laser ultrafine marking & Laser Structuring

- Laser Micro Welding

- Hybrid Laser Micro Machining System

- Laser Patterning on Thin film solar cells

- Laser Patterning on large area electronics

- Laser Patterning for advanced IC packaging

Gallery

Videos

Enquiry

For Micro Laser Patterning System enquiry and to discuss more about your application requirement, with one of our laser engineer. To know Laser Micro Machine price, Please call us direct on +91 9789904948 or Visit our regional office or complete the request form and we will contact you, as soon as possible. We United Spectrum company also offer the best quality laser marking, laser cutting, laser texturing, laser engraving, laser cleaning, laser welding, laser cladding, laser hardening, laser shock peening, laser micro machines in India.